Glossary

Logout

©Copyright Arcturus 2022, All Rights Reserved.

7

Terms & Conditions

|

|

|

|

Security & Privacy

Contact

PROCUREMENT

|Generic Ideas, Suggestions & Tips

Reduce the number of suppliers.

The principle of simplification is also valid for the procurement channel.

Fewer suppliers mean fewer interfaces, less training, less administrative work, etc. and will have a favourable influence on the amount of staff needed and the costs involved. There are other effects to be added. In the new vendor relations pattern close personal contact has to be maintained. In principle just-in-time supplies are handled on the basis of on-line information, but in case of problems (even small ones) fast action is needed by persons who have regular contacts. This is only possible when the total number of suppliers is limited.

Greater flexibility is achieved when one vendor supplies several parts, than when every part is supplied by a different vendor. For example, when vendor A supplies cabinet 1 and vendor B supplies cabinet 2 and the planning indicates a change from product 1 to product 2, and this situation is later reversed again, vendors have to change capacity twice. One vendor has to stop, the other vendor has to start, which creates problems and costs for all parties concerned.

If one single vendor had supplied both cabinets the changes would only have involved exchanging a mould on one machine.

This is only one example that demonstrates the clear and measurable advantages resulting from reducing the number of suppliers.

Active reduction of the number of suppliers should be part of the action programme of all procurement and purchasing organisations.

Measure the lead time for information from point-of-sale to component or material supplier.

If we measured the time that elapses before a dealer’s actual sales transaction is translated into a signal to the ultimate component or material supplier, we would be in for an unpleasant surprise. Take into account manufacturing lead times, where physical factors, like processing time, transportation times etc. provide a certain limitation to what we can ultimately achieve.

Information, however, has no basic physical limitations. Nevertheless we may assume that in many cases the total lead time for planning information may be of the same order of magnitude as the lead times in manufacturing. This is a good reason for analysing this process thoroughly and seeking ways to speed it up. It is an essential part of the total reaction speed of the company.

|Strategic Business Models, Workshop Tools & Professional Resources

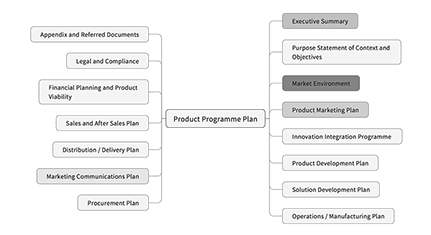

The IPM practitioner series, is a definitive and integrated training programme for management professionals operating in the Product Management arena. So whether you’re the Managing Director, Product Director, Product Manager or a member of the Multidisciplinary Team we are confident that you will find this particular training series to be one of the best available and an invaluable asset to both you and your company.

PMM - Professional Support