Glossary

Logout

©Copyright Arcturus 2022, All Rights Reserved.

7

Terms & Conditions

|

|

|

|

Security & Privacy

Contact

PRODUCT MANAGEMENT TRANSFORMATION

Following Method

Focused and dedicated situational analysis is a fundamental starting point for any ‘strategic alignment’ activity going forward. Managing change, continuous improvement and business transformation all start form the same fundamental line of thought:

‘Where are we now’, ‘where do we want to be’ and ‘how do we get there’.

Perhaps the most important message here is, don’t change for the sake of change. There must be clear strategic rationale and agreement going forward. Thereafter continuous improvement measurements and targets are the fundamental key for continued success. Deploying strategic intent is where most companies have a problem. Unless we are talking about a small enterprise, where everyone ultimately understands what everyone else is thinking the cascade of Objectives and Strategies become a real challenge. For many the lowest common denominator is a style of ad-hoc management activities.

Putting this into context the PMM process is a professional framework for managing products and services across their entire lifecycle. Described in some detail within this site (Arcturus7.com), it could be deployed in its generic form or indeed customised to meet your own company’s requirements – please don’t let anyone dissuade you from this fact. From small businesses to large corporate enterprise the core PMM thinking / architecture is eminently scalable. Having access to an industry proven process building block / architecture will save you time, effort and commercial risk.

Method by definition in this context, is the way products / services are planned so that action can be taken in an orderly and systematic way with the provision of requisite resources. Right method is crucial for success, as is the ability to optimise the method to achieve best results, the PMM process and associated tools delivers this together with a level of flexibility.

‘Right method ensures change is directed toward continuous improvement’.

In practice the methodology is an eminently scalable end to end Product Management work flow process. Once deployed it enables ‘Product Managers’ to manage their products in a robust and yet flexible manner via a continuous business planning activity.

Robust Method can be used as a powerful catalyst for change itself or be part of a much larger transformation project. ...It is often the case that the implementation of the PMM process is part of a larger business transformation project but it is equally applicable to specific business units or individual product lines.

|Business Processes, Method & Transformation

‘Hover and Click’

Adopting correct process method companies can very quickly realise the benefits from achieving breakthroughs in their business performance, as perceived by their customers and other stake-holders.

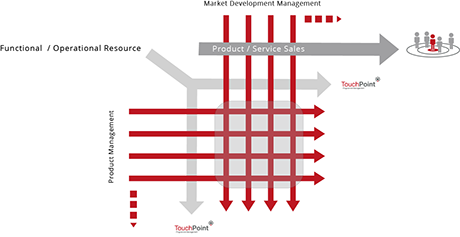

A functionally biased organisation is inherently less efficient (with a direct correlation to its physical operational size) than those with dynamic multidisciplinary approach. Better co-operation across functional and geographical barriers is often needed to realise the benefits. This in turn can be fulfilled by the introduction of an additional organizational framework: the process organisation. The process organisation needs to be systematically structured, planned, controlled and led. It is therefore a management task to introduce and manage this new organisational dimension: Process Management.

Process Management is without doubt a critical success factor. Without structured method and Process Management, objectives will simply not be achieved. Process Management is the method by which the voice of the customer can make itself heard in every part of our business. Without method and clearly defined processes, Implementation of a business transformation programme is understandably a major challenge for all managers concerned.

|Definition and The Importance of an Integrated Cross Functional Approach (in context)

Integrating process and ‘method’, into a business it can very quickly realise the benefits, achieving breakthroughs in their product / service business performance.

Academia have cited on many occasions, that a ‘functionally’ orientated organisation is inherently less efficient and effective (with a direct correlation to the operational size) than those operating a ‘dynamic’ cross functional, multidisciplinary approach. In practice however, many businesses remain steadfast in following a ‘functional’ approach. So why is this the case? …there is of course no simple answer to the question as there are several valid reasons for the traditional approach, not least because it’s apparently understood, however for many businesses, it is simply based on historically rationale.

As a general observation, any company or businesses that possesses a ‘portfolio’ of products / services and or are marketing products to ‘geodemographic markets’, will almost certainly benefit from a cross functional strategic management approach. It is also clear, that without well-defined method or processes in place, a series of random acts duly make management activities thereafter a challenge for all concerned.

When a cross functional approach is accepted and the need for change acknowledged, senior directors and/or the management team must all buy in to the agreed approach followed by co-operation across functional and geographical barriers. At this point, it goes without saying that a process organisation needs to be systematically structured, planned, controlled and programme led, but in saying that, individual functions must remain as the pillars of delivery.

A process can be defined as a chain of events whereby a ‘transformation’ or ‘action’ takes place at each event and/or process step. In principle, every activity of a process should add value to the preceding stage, ultimately leading to the satisfaction of an external customer or other stake-holders.

Core competencies / capabilities of different individuals and the resources of different departments can all be linked together by processes to produce joint value for the customer of the process. Some processes are clearly visible as streams of material: production processes and physical distribution processes are well-known examples and can be readily observed. In other processes the streams are mainly flows data or information.

The fundamental purpose of a business process is to strategically control key functional areas of the business that directly relate to ‘critical’ success factors. The result is embedded repeatability, rigor and robustness. The PMM process is very much in this frame as it relates to every functional area within the business and impacts directly to the value proposition. Process of this type ‘orchestrate’ activities and bring together functional areas together with defined strategic objectives.

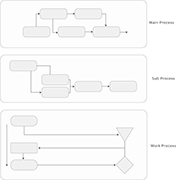

|Process Structure

Main processes typically contain a network of sub-processes, which in turn are assemblies of work processes, resulting from a cascade of interlocked objectives and strategies. It is in a work process that the actual transformation of material, energy and information takes place.

|Why Process Management...?

In today’s competitive environment we need a formula that embraces and can effectively deliver in an environment of continuous improvement. This in turn is being driven by Customers ‘Voice Of the Customer’ demanding more from products and services in a self-perpetuating way. Process Management therefore offers a genuine solution to this problem. At the same time, it also allows management to focus on the Voice Of the Business and strategically align the company with higher efficiencies and lower costs expectations.

The ‘functional organisation’ has proven its value over time, but equally the disadvantage’s and shortcomings have become progressively more visible than ever before. In today’s business environment with all the pressures that come to bare, the focus on developing and maintaining a competitive edge has become a lot harder. Agility, lean and continuous improvement is therefore an accepted starting point. In the past, differential alignments and creative initiatives safeguarded the establishment by the individual functions themselves. This approach was relatively successful however, in many cases, the opportunities for further improvements along individual functions have long since diminished due to the rather ad-hoc approach.

Management ‘processes’ aligned for delivering both competitive edge and ‘Customer’ value fundamentally cut through the organisation, integrating / crossing functional areas, bringing together the required competencies at the right time, on time, every time. These processes should deliver repeatable, measurable qualities which in turn lead to strategically aligned commercial success (if deployed correctly). The PMM process (frameworks) is a perfect example of a multidisciplinary end to end process that efficiently and effectively managers a product / service ‘programme’ across its entire product lifecycle.

|Process Management

Process management programmes (including the ‘PMM’ process) add a new dimension to multidisciplinary functional Management. Process Management is ultimately owned, introduced and driven by the strategic management team. Process Management consists of several, interlinked components / activities.

Setting process measures, control, and maintenance all form the basis of best practice process management programmes. Once deployed, systematic evaluation (continuous improvement) and performance of the process leads to corrective actions and ultimately means that the process remains fit for purpose and delivers as expected.

Process method and maintenance programmes assures the repeatability of every processes per standards and procedures. ISO9000 etc., could theoretically be applied to any documented process.

A culture of continuous process improvement continuously improves the process capabilities, which in turn indirectly leads to improvements in the commercial viability of the product(s) concerned. Process improvement is stimulated and facilitated by management but everyone participates. Iterative and continuous improvement should be a fact of life within every process driven multidisciplinary team.

...focuses on business priorities

- By deploying business priorities into objectives for controlling, improving and (re)designing processes...

- By analysing the process structure and improving insight into cause and effect relationships...

- By establishing ownership for process control, improvement and (re)design and stimulating the allocation of resources...

- Process Management establishes an environment in which leads directly to competitive advantage as perceived by customers.

...focuses people on processes...

- By making processes visible...

- By making the process structure manifest...

- By providing a framework for understanding how a business provides value to customers...

- By linking the contribution of people to the improvement of processes which create value for the customer...

- By determining and explaining priorities of the various processes...

- By encouraging people to add the process dimension to their functional orientation through involvement in process-directed activities...

|Implementation

The implementation of Process Management requires a new attitude and new capabilities from functional managers and the organisation.

- A need to demonstrate understanding of what processes are and what process management means for customer satisfaction and hence business success.

- A need to explain why the functional organisation is still needed but is no longer sufficient to achieve the necessary improvements.

- A need to explain how it will affect individuals within the organisation and what training will be required.

|The Need to own the Process

A process-oriented ‘Product Management’ activity is required to manage a cross functional organisation. Product / Market development managers will require to have the specific tasks to own one or more ongoing processes, starting at the level of main processes and moving all the way down to the work processes. Ownership implies that managers accept the responsibility for an entire process across all functional barriers.

It is the task of the process / programme owners to make the process visible (mapping), to agree on the performance targets for the process (policy deployment), to measure the actual performance of the process (performance monitoring) and to take measures to improve process performance if necessary.

The appointment of process owners for all main, sub, and work processes results in a structure of process owners superimposed on the functional hierarchy.

| Process Control and Improvement

Most organisations have capabilities for process control and maintenance. Tools and methods for their implementation and for the supervision of their effectiveness are provided by the Quality Control & Assurance function, supported by Quality systems and standards such as ISO 9000. Statistical Process Control (SPC) is one of the well-known tools for process control in many areas.

Continuous process improvement

Most continuous process improvement is undertaken by quality improvement teams. Several types of teams exist. Some have a departmental nature, others have members from a variety of functions (cross functional teams). Many improvement actions, if added up, may lead to impressive total process performance progression.

It is by now understood that if process improvement is demanded, rather than activity improvement, teams with a multi-functional composition are required. Improvement teams use the ‘Deming’ PDCA (Plan-Do-Check-Act) cycle.

Many tools are available for continuous process improvement. Well known, although still insufficiently applied, are the seven statistical tools, the seven management tools, tools to prevent problems (like FMEA; Failure Mode and Effect Analysis) and tools to make processes visible and open to analysis (like flowcharting and bottleneck analysis).

| Business Process Transformation

Business Processes and Support Processes may have been intentionally designed to meet the requirements of the function concerned. This certainly is the case for physical processes like production and physical distribution.

The Product Creation Process has often been intentionally designed and/or redesigned to achieve improvements in process performance. For example, the process cycle time will be drastically reduced and is better controlled. Development process in the form of StageGate, Lean, Agile, Scrum have all added to the efficiency and effectiveness of the development activity.

The Development is a good example of processes that have been honed by experts over a considerable period of time however other Business and Support Processes may not have developed accordingly or deliberately. Many of these processes are not visible; neither are they explicitly managed.

Responsibilities for process design, monitoring, evaluation, improvement, and redesign have not been defined and therefore can be rightly or wrongly subjected to ad-hoc management activities.

Competitive advantage which is required or aimed at cannot be achieved without clearly defined ownership of improvement, design and redesign of Business and Support Processes. This in turn promulgates the need for a process re-design.

| Business Process Redesign

Process redesign can be divided into three phases: discovering the needs and opportunities, the actual redesign, and the implementation.

Discovering the needs, opportunities and conditions

This phase aims at identifying the key processes in a business organisation, assessing needs and opportunities for improvement, and selecting specific processes for redesign. The definition of redesign objectives is the result of Policy Deployment.

The management team takes the following steps:

Agree on critical success factors

Understanding which success factors drive competitive advantage in the business. Examples of critical success factors are: lead time to market, speed and reliability of supply and life-time costs. Using Policy Deployment, the critical success factors and their relationship with Business Processes can be defined.

Identify key processes

Determining which Business Processes have the highest impact on the desired business performance. These are the key processes. Key processes have the highest priority in redesign. There may also be other reasons such as malfunctioning or inconsistency which may in turn lead to a high priority for redesign.

Prepare for change

Appointing one of the management team members as owner for each process to be redesigned or interfaced thereto. The owner has the authority to act on behalf of the team and reports to that team.

Assess the opportunities for breakthrough

As business process performance improves, so does the customers’ perception of value. Competitors also continuously improve their processes. Generally, there will be a definable performance level - measured in cost, product quality, service or cycle time - that will lead to a disproportionate gain in competitive advantage. This is the breakthrough level.

An important tool for identifying breakthrough opportunities and facilitating implementation is competitive benchmarking. It implies searching and studying best practice processes in other industries. It is also vital to establish a clear understanding of an agreement upon customer needs and perceptions.

|Key Point

Focus on value for the Customer

Integrated process management keeps the organisation focusing its attention on value for customers and the business processes which create that value. Simultaneously it supports the identification of organisational efficiency and effectiveness. The Product Management Methodology (PMM) delivers the key architectural principles required to manage the cross functional organisational interrelationships.

Focus on processes, not functions, follow method

The processes which create value for customers cut across the interfaces between functions. Interfaces may be barriers for improvement. Process management creates a new dimension in addition to the functional division of tasks and responsibilities.

Focus on the individuals who must make it happen

Process management implies business wide change.

The success depends first on the people who are involved. It is a management task to explain, train, coach and be involved and thus stimulate people to participate fully.

Focus on all processes

Process management addresses the entire process dimension, even if there is a priority for the redesign of key business processes. The basis for process management is continuous improvement of all processes, in which all people must be involved, as well as relevant business partners.

Focus on stretching targets – design a culture of continuous improvement.

Stretching targets force the organisation to change the way it thinks and acts. Only stretching targets will enable us to surpass the performance of competitors and to be perceived by customers as the best.